What Are Nahttypen

Definition of Nahttypen

Nahttypen refers to the different seam types used in sewing. Seams are essential in joining fabric pieces together, whether for functional or aesthetic purposes. They play a vital role in the construction of garments, ensuring the fabric fits together well and holds up over time. Each type of seam serves a specific function, such as adding strength, providing flexibility, or enhancing the garment’s visual appeal.

Seams are often classified based on their construction method and intended use. A simple seam could be used to join two fabric pieces, while a more complex one may be used for decorative purposes or to provide extra durability. The right seam ensures a garment is comfortable, long-lasting, and visually appealing.

Importance of Seam Types

Seam types impact the durability, strength, and overall appearance of a garment. The choice of seam will influence how well a piece holds up to wear and tear, the type of fabric it can support, and the overall look of the finished product. This is why understanding seam types is crucial for anyone working with fabrics.

Durability and Strength

Seam types affect how durable a garment is. Certain seams are designed to withstand stress and are more suitable for heavy fabrics like denim. For example, flat-felled seams are known for their strength, making them ideal for high-stress areas like jeans. On the other hand, lightweight fabrics may benefit from seams like the French seam, which offers a clean, delicate finish.

Aesthetic Appeal

Seams also contribute to the overall aesthetic of a garment. Decorative seams, such as topstitching, add an extra touch to items like evening wear. In contrast, seams like the blind hem ensure a clean finish for formal clothing without visible stitching. Choosing the right seam can elevate a garment’s design, ensuring that it is both functional and stylish.

Flexibility and Fit

Certain seams, like the zigzag and overlock seams, are particularly useful for fabrics that require flexibility, such as stretch fabrics or knits. These seams allow the fabric to maintain its elasticity, ensuring a better fit and comfort for the wearer. Activewear, for instance, benefits from these seams because they allow the fabric to stretch and move with the body.

Common Seam Types

There are several types of seams used in sewing, each serving a distinct purpose. The most common types include plain seams, French seams, flat-felled seams, and overlock seams, among others.

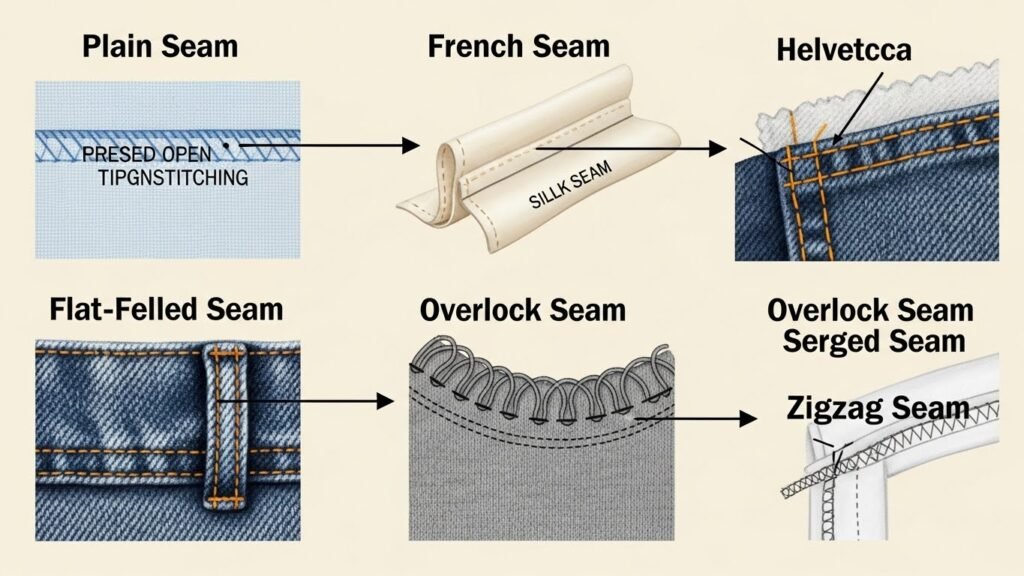

Plain Seam

A plain seam is the most basic and commonly used seam in sewing. It involves joining two fabric pieces with a straight stitch along the edges. This seam is ideal for woven fabrics and non-stretch textiles. However, it often requires additional finishing to prevent the edges from fraying.

French Seam

The French seam is a double-stitched seam that encloses the raw edges of the fabric. This type of seam is ideal for lightweight fabrics like silk and chiffon. It provides a polished interior, preventing fraying and giving the garment a clean, professional finish.

Flat-Felled Seam

The flat-felled seam is strong and durable, commonly used in heavy fabrics such as denim. This seam is often used in jeans and workwear, as it offers both a clean finish and durability. It involves folding the fabric edges inside the seam, which not only hides raw edges but also strengthens the join.

Overlock Seam

The overlock seam is created using an overlock machine that trims the edges of the fabric while stitching them together. This type of seam is especially useful for knitwear and stretchy fabrics, as it prevents fraying and ensures the seam remains strong. It’s commonly used in activewear and other garments that require a flexible and durable finish.

Zigzag Seam

The zigzag seam is commonly used for knit or stretch fabrics. This seam allows for elasticity, making it perfect for garments that need to stretch, like T-shirts and leggings. The zigzag pattern prevents the fabric from fraying and maintains the garment’s flexibility.

Lapped Seam

A lapped seam is created by overlapping one fabric layer over the other before stitching. It is ideal for thicker fabrics like leather and denim. This seam provides a sturdy, visible finish, making it popular for garments that require extra strength.

Bound Seam

Bound seams use fabric strips or binding tape to enclose the raw edges of the fabric. This seam is commonly used for delicate fabrics and garments that require a polished interior. It offers a clean and neat finish, often seen in formal wear and high-quality garments.

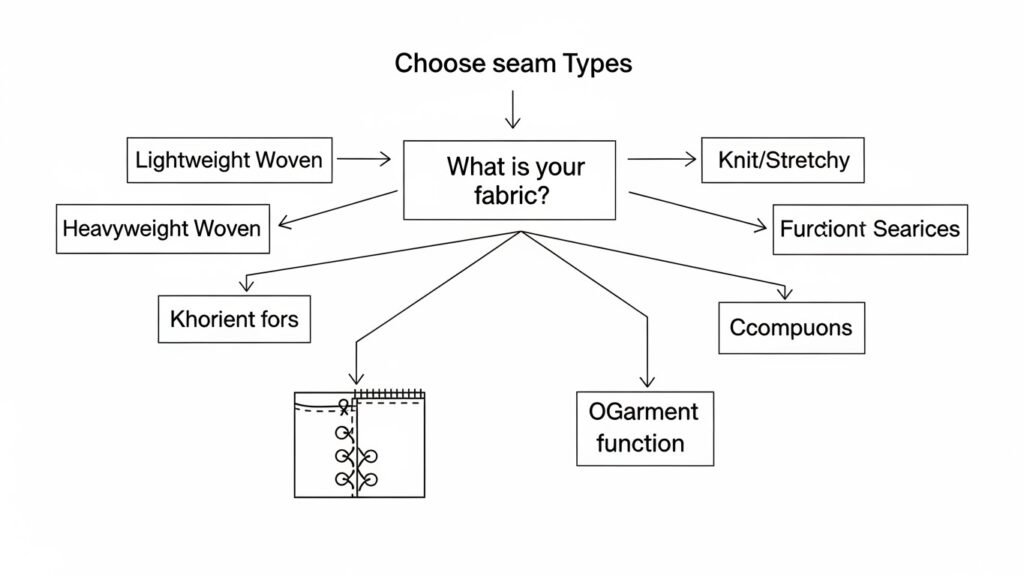

How to Choose the Right Seam Type

When selecting a seam type, it’s essential to consider several factors, such as the type of fabric, the intended use of the garment, and durability needs. The right seam can improve the garment’s overall appearance and ensure it performs well over time.

Based on Fabric Type

- Cotton: Plain, French, or Flat-Felled Seams

- Denim/Heavy fabrics: Flat-Felled, Lapped Seams

- Lightweight fabrics: French, Bound Seams

- Stretch fabrics (knits): Zigzag, Overlock Seams

- Leather: Lapped, Bound Seams

Based on Garment Function

- Casual wear: Flat-Felled, Overlock, Lapped Seams

- Formal wear: French, Bound, Blind Hem Seams

- Activewear/Stretch: Overlock, Zigzag, Flatlock Seams

- Heavy-duty garments: Flat-Felled, Double-stitched Seams

Based on Durability Needs

- High-stress areas (e.g., pants, jeans): Reinforced seams like Flat-Felled or Double-stitched Seams

- Stretch areas (e.g., T-shirts, leggings): Flexible seams like Zigzag or Overlock Seams

- Light fabrics (e.g., silk, chiffon): Enclosed seams like French Seams to prevent fraying

Decorative and Functional Seam Types

Seams not only contribute to the structural integrity of a garment but can also add decorative elements. Whether functional or purely ornamental, seams are an essential part of garment design.

Decorative Seams

- Satin Stitch: Often used for ornamental purposes, particularly in embroidery.

- Topstitch: Adds both strength and a decorative touch, commonly seen in denim or formal wear.

- Blind Hem: Nearly invisible and used for hemming formal pants, skirts, and dresses.

Functional Seams

- Straight-Stitch Seam: Used for basic, everyday sewing on woven fabrics.

- Overlock Seam: Perfect for finishing edges and ensuring durability.

- Flatlock Seam: Ideal for athletic and stretchy garments, lies flat against the body.

Seam Finishing Techniques

Proper seam finishing is essential to ensure that the garment remains intact and looking professional. There are various methods for finishing seams, including overlocking, pinking shears, and binding.

Methods and Their Purpose

- Overlocking: Prevents fraying and strengthens the seam.

- Pinking Shears: Cuts fabric edges in a zigzag pattern to prevent fraying.

- Binding: Encloses raw edges for a polished, professional finish.

- Double Stitching: Adds durability, especially in high-stress areas.

- Serging: A technique that finishes both the stitch and the edge in one step, commonly used in knit fabrics.

Common Mistakes with Seams and How to Avoid Them

While sewing, several mistakes can occur if the wrong techniques are used. It’s important to recognize and avoid these errors to ensure your garment turns out perfectly.

Using the Wrong Needle Type

Heavy fabrics need thicker needles, while delicate fabrics require finer needles. Always match the needle type to the fabric’s weight and stretchability.

Not Finishing Seam Edges

Unfinished raw edges will fray over time, weakening the garment. Be sure to finish edges using overlocking, pinking shears, or binding.

Incorrect Tension Settings

Too tight or too loose stitching can weaken the seam. Always test the tension on scrap fabric before sewing the final garment.

Failing to Choose the Right Seam Type for Fabric

Using a rigid seam for stretch fabrics can cause distortion. Choose seams like overlock for stretchy fabrics and flat-felled for heavy-duty fabrics.

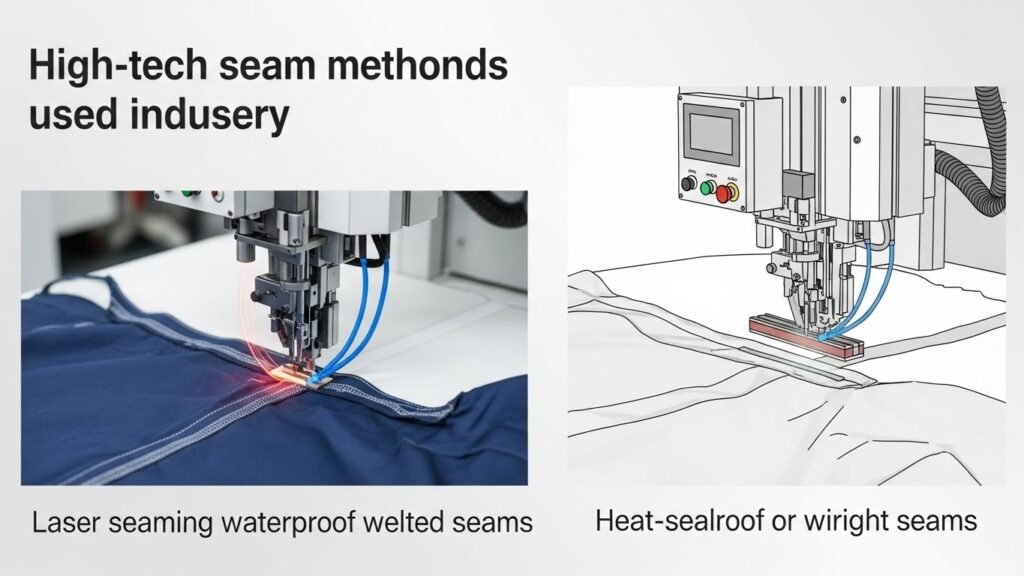

Advanced Seam Methods in the Industry

In the world of garment manufacturing, new seam methods have emerged, especially for large-scale production. These advanced techniques help meet the growing demand for specialized fabrics and high-performance garments.

Modern Techniques in Large-Scale Production

- Laser Seaming: This method uses laser technology to join fabrics without thread, providing a clean and precise seam. Laser seaming is particularly useful for creating specialized garments that require high precision and durability, such as protective clothing and activewear. It is widely used in industries that need garments to meet strict performance standards.

- Heat Sealed Seams: Heat sealing involves using heat to bond fabric pieces together, creating waterproof or airtight seams. This is particularly useful in the production of raincoats, outdoor gear, and other garments that need to be resistant to water or other environmental factors.

- Welded Seams: This method uses heat and pressure to fuse fabric without the need for stitching. Welded seams are common in high-performance gear, such as wetsuits or outdoor jackets, where water resistance is critical.

- Conductive Seams: With the rise of wearable technology, conductive seams have become increasingly important. These seams allow fabrics to conduct electricity, making them suitable for smart clothing and wearable electronics. They are used in garments that have built-in sensors or need to interact with electronic devices, such as fitness trackers or temperature-regulating fabrics.

Seam Type Selection Checklist

When selecting a seam type for your sewing project, it’s important to follow a set of guidelines that match the fabric’s characteristics and the garment’s intended use. Here’s a checklist to guide your selection process.

Key Considerations When Choosing a Seam

- Fabric Type: The fabric’s weight and stretchability will determine the most suitable seam type. For instance, lightweight fabrics like silk and chiffon work best with French seams, while heavy-duty fabrics like denim require strong seams like flat-felled seams.

- Garment Function: Choose seams that fit the garment’s purpose. Casual wear may benefit from overlock or flat-felled seams, while formal wear may require cleaner seams like French or blind hem seams.

- Aesthetic Preferences: Consider whether the seam will be visible or hidden. For example, topstitching can be decorative and visible, while a blind hem seam will remain hidden, making it ideal for hems of formal garments.

- Durability Requirements: High-stress areas, like the crotch or seat of pants, may require reinforced seams. For areas with less wear, lighter seams like French seams or overlock seams may suffice.

- Finish: Ensure that the raw edges are finished to prevent fraying and ensure longevity. Using pinking shears, overlocking, or binding can help protect the raw edges from damage.

Final Thoughts on Seam Types

The right seam type can make a significant difference in how a garment fits, performs, and lasts. Understanding the strengths and weaknesses of different seam types allows you to make informed decisions that improve the quality of your sewing projects.

Experiment with Different Seams

Don’t be afraid to experiment with different seam types to achieve unique and professional finishes. Whether you’re designing a garment for everyday wear or something more intricate, the right seam will elevate the overall look and function of the piece.

Consider Fabric, Purpose, and Durability

Always keep in mind the fabric type, intended use of the garment, and the durability required when choosing a seam. This ensures that your garment will not only look good but also stand up to wear and tear, providing long-lasting comfort and style.

Seam Finishing and Maintenance

Proper finishing techniques like overlocking and pinking shears are essential for preventing fraying and maintaining the garment’s integrity. Additionally, maintaining your seams with proper care during washing and wear ensures that your garments continue to perform well over time.

The Role of Seam Types in Garment Comfort and Fit

Seams are not only structural elements but also play a critical role in the comfort and fit of garments. The wrong seam type can make a garment feel restrictive or uncomfortable, while the right one enhances movement and ensures a better fit.

How Seams Affect Comfort

The right seam ensures that the fabric fits comfortably on the body and moves with it. For example, seams used in activewear need to allow for flexibility and stretch. On the other hand, seams in more rigid fabrics like denim must provide a firm, stable structure. The choice of seam type determines how a garment feels when worn, which is especially important for clothing worn throughout the day.

- Zigzag Seams: These are ideal for stretchy fabrics, as they provide the necessary elasticity for activewear and knit garments.

- Overlock Seams: These are great for garments that require a snug fit while still offering flexibility, like T-shirts and leggings.

Seams and the Fit of Garments

Seams also determine the overall fit of a garment. A well-fitted garment requires seams that allow for the natural shape of the body, while also considering the fabric’s stretch. For instance, overlock seams are great for garments that need to hug the body, such as leggings. Meanwhile, seams like the French seam are used for a more refined fit, especially in lighter fabrics where a clean finish is desired.

- Lapped Seams: These seams work well for thicker fabrics and leather, ensuring a fit that’s sturdy and structured.

- Flat-Felled Seams: Often used in jeans, these seams provide a strong fit and can be reinforced for areas under stress, such as the inner leg or waistband.

Stretch and Movement in Garments

When selecting a seam type for garments that require stretch and movement, it’s important to choose seams that allow for flexibility. For garments like sportswear or swimwear, the right seam ensures that the fabric stretches without breaking. Seams like the zigzag or overlock are great choices for garments that need to move and stretch with the body.

Advanced Applications of Seam Types

Seams aren’t just for traditional sewing projects; they have been adapted for advanced applications in various industries, including sportswear, medical textiles, and even wearable technology.

Seam Types in Sportswear

Sportswear relies heavily on seams that are both durable and flexible. The choice of seam directly impacts the comfort and performance of athletes. For example, overlock seams are commonly used in workout clothing due to their ability to stretch with the fabric, ensuring that athletes can move freely without restrictions.

- Flatlock Seams: Commonly found in high-performance sportswear, flatlock seams lie flat against the body, reducing friction and discomfort during physical activity.

Seam Types in Medical Textiles

In medical textiles, seams play a vital role in ensuring that garments are not only functional but also comfortable for extended wear. These garments often need to be sterile and easy to clean, which is why seam choices are critical. For example, welded seams are increasingly used in medical garments as they create a strong, waterproof barrier, which is important in the medical field for ensuring sterility.

Seam Types in Wearable Technology

With the rise of wearable technology, new types of seams are being developed to integrate electronics into textiles. Conductive seams, for instance, allow for the integration of sensors and wires within clothing without compromising comfort or durability. This technology is found in garments like smart jackets or fitness trackers, where the seams must be able to conduct electricity while remaining functional and comfortable.

- Conductive Seams: Used in garments like smart clothing, conductive seams are a significant development in wearable tech, allowing fabrics to interact with electronic devices.

Seam Construction Techniques for Professional Results

For those looking to achieve professional results in their sewing projects, mastering advanced seam construction techniques is essential. These techniques ensure that the seams are not only strong and functional but also visually appealing.

Double Stitching for Reinforced Strength

In areas that experience high stress, double stitching adds extra reinforcement to seams. This technique is commonly used in garments like jeans or workwear, where the seams must withstand repeated wear and pressure.

- Double Stitching: By sewing two lines of stitches, the seam gains extra durability and can handle more stress, ensuring the garment lasts longer.

Topstitching for Visual Appeal

Topstitching is a technique used to add a decorative touch to seams. It’s often seen in denim and formal wear, where it adds both strength and a visual element to the garment. The right use of topstitching can elevate a garment, giving it a polished, professional look.

- Topstitching: This is often done along the seam or hemline, adding both structure and aesthetic appeal to the garment.

Blind Hem for Invisible Finishes

For garments like skirts and formal pants, the blind hem is often used to create a seamless, invisible finish. This technique ensures that the hem is neat and tidy, without visible stitching. It’s ideal for formal occasions where a clean and professional appearance is necessary.

- Blind Hem: This technique is essential for hemming formal wear and garments that require a flawless, nearly invisible seam.

The Science Behind Seam Durability

Understanding the durability of seams is key to ensuring that garments not only last longer but also maintain their integrity under various conditions. Seams are subject to wear and tear, so it’s essential to choose the right type for the fabric and intended use.

Fabric Properties and Seam Durability

The type of fabric plays a critical role in determining the durability of a seam. For instance, heavy-duty fabrics like denim or canvas require stronger, reinforced seams, while lighter fabrics like silk or chiffon benefit from more delicate, enclosed seams.

- Heavy Fabrics: Fabrics like denim, canvas, and leather demand seams with reinforced strength. Flat-felled seams are perfect for such applications as they provide both durability and a clean finish.

- Light Fabrics: Silk, chiffon, and other lightweight textiles require seams like French seams or bound seams that enclose raw edges to prevent fraying and maintain a delicate structure.

Stress Points and High-Pressure Areas

Certain areas of a garment experience more stress, such as the crotch area of pants or the elbows of jackets. In these high-pressure areas, the choice of seam becomes critical to ensure the garment withstands regular use.

- Reinforced Seams: Areas like the crotch or inner thighs of pants often benefit from reinforced seams like double-stitched or flat-felled seams, which prevent breakage and increase the garment’s longevity.

Environmental Factors and Wear Resistance

Garments are often exposed to different environmental factors, such as heat, moisture, and friction, which can affect the seam’s durability. For example, seams on outdoor wear, like jackets or raincoats, must withstand exposure to rain, snow, and UV rays.

- Waterproof Seams: In garments meant for outdoor activities, waterproof seams or welded seams help keep moisture from entering the fabric and prolong the garment’s wear life. These seams are particularly useful in high-performance clothing such as rain jackets or outdoor gear.

Sustainability and Eco-Friendly Seam Techniques

With the increasing demand for sustainability in the fashion industry, eco-friendly seam techniques are becoming more important. Sustainable practices help reduce waste, improve garment longevity, and minimize the impact of textile production on the environment.

Sustainable Seam Finishing

Traditional seam finishing methods, like overlocking and pinking shears, can generate a lot of fabric waste. In response, sustainable seam finishing techniques are being developed to reduce waste and improve the environmental impact of garment production.

- Eco-friendly Overlocking: Some overlocking machines now use more sustainable materials and processes, which minimize waste and improve the overall efficiency of garment production.

- Natural Thread: Using natural, biodegradable threads instead of synthetic ones helps reduce the environmental footprint of sewing projects, making them more eco-friendly.

Upcycling and Repurposing Seams

Upcycling garments by adding or altering seams to create new designs is an eco-conscious approach to fashion. By reworking old clothes, you can give them a new life while reducing textile waste.

- Repurposing Seams: Upcycling can involve adding new seams or adjusting existing ones to make the garment fit better or give it a completely new look. This method extends the life cycle of the fabric, reducing the need for new materials and lowering waste.

Recycling Fabrics with Minimal Seam Waste

Innovative techniques like laser seaming are helping to reduce fabric waste during garment production. These methods join fabrics together using precise cutting and seaming techniques, allowing for more efficient use of the material.

- Laser Seaming: By using lasers, manufacturers can join fabrics without the need for thread, significantly reducing material waste and producing cleaner, more durable seams.

Understanding Seam Tension and Stitch Quality

The quality of a seam depends largely on the tension settings used during stitching. Improper tension can result in weak seams that either break under pressure or do not hold the fabric properly.

How Thread Tension Affects Seams

Thread tension is crucial for creating strong and durable seams. Too tight a tension can cause the fabric to pucker, while too loose a tension can lead to weak seams that may unravel over time. It’s important to adjust the tension based on the fabric type and the seam type being used.

- Optimal Tension: For most fabrics, medium tension works best. However, stretchy fabrics, like knits, require a slightly looser tension to prevent the fabric from distorting or puckering.

Stitch Quality and Seam Integrity

The quality of the stitches directly impacts the integrity of the seam. A consistent, even stitch ensures that the fabric is held securely and will not easily pull apart. Low-quality stitching, on the other hand, can lead to weak points in the seam.

- Sewing Speed and Pressure: Sewing too quickly or with too much pressure can affect stitch quality. It’s important to maintain a steady, controlled pace to ensure the stitches are evenly spaced and consistent.

Testing Seams for Strength

Before committing to a specific seam type for a final project, it’s a good idea to test the seams on a scrap piece of fabric. This helps to ensure that the tension is correct and the seam holds well under stress.

- Seam Testing: Testing different types of seams and stitching techniques on scrap fabric ensures that you get the desired effect and strength in your final garment. It’s always wise to check the durability and flexibility of a seam before using it in a real project.

Troubleshooting Common Sewing Problems with Seams

Even experienced sewists encounter problems while working with seams. Understanding how to troubleshoot common issues can save time and effort in the long run.

Seam Ripping and Unraveling

One of the most common issues faced when sewing seams is seam ripping or unraveling. This often happens when the wrong seam type is chosen for the fabric, or the tension is set too loosely.

- Seam Ripper Tool: When seams fail, a seam ripper is a useful tool for undoing stitches without damaging the fabric. After ripping out a faulty seam, make sure to re-sew with the correct tension and stitch settings to avoid the issue reoccurring.

Puckering or Fabric Distortion

Puckering occurs when the fabric bunches up along the seam. This can happen if the stitch tension is too tight or if the wrong seam is used for the fabric type.

- Preventing Puckering: To avoid puckering, always test your stitching on scrap fabric. Ensure the fabric is smooth before stitching, and adjust the tension as needed.

Uneven Seams or Stitching

Uneven seams are often the result of inconsistent stitch lengths or improper feed of fabric through the sewing machine. This can cause certain areas of the seam to be tighter than others.

- Consistent Stitching: Keeping the fabric aligned properly and ensuring that the sewing machine feed dogs are working correctly will help maintain even stitching throughout the garment.

The Future of Seam Technologies in Fashion

As technology continues to advance, seam technologies are evolving to meet the demands of modern garment production. Innovations in seam construction are not only making garments more durable and functional but also contributing to sustainability in fashion.

3D Seam Printing and Automation

The future of seam technologies involves 3D printing and automated sewing systems. These technologies offer the potential to create more precise and intricate seams, improving both the aesthetics and durability of garments.

- 3D Printing of Seams: The use of 3D printing technology allows manufacturers to print seams directly onto fabrics, eliminating the need for traditional sewing. This method offers precise control over the placement and construction of seams, making it ideal for high-performance textiles.

- Automated Sewing Systems: Automated sewing machines equipped with advanced algorithms can sew garments faster and with greater accuracy. These systems reduce the potential for human error and improve the overall quality and consistency of seams in mass production.

Seamless Garments and Performance Enhancements

Another trend in the fashion industry is the move toward seamless garments. By eliminating traditional seams, manufacturers can create garments that are more comfortable and reduce the risk of irritation from stitching.

- Seamless Technology: Seamless garments are created by knitting the fabric in one continuous piece rather than sewing pieces together. This technology has been widely adopted in activewear, swimwear, and sportswear, where comfort and flexibility are key.

- Performance Fabrics: Seamless garments often incorporate performance fabrics, which are designed to offer enhanced breathability, moisture-wicking, and support. This is particularly useful for athletes who need garments that perform well under strenuous conditions.

Smart Seams and Wearable Electronics

With the rise of wearable technology, the future of seams is becoming more tech-oriented. Smart seams, which incorporate conductive threads, sensors, and electronics, are revolutionizing how garments interact with the wearer.

- Conductive Thread Seams: These seams use conductive threads that allow the garment to transmit electrical signals. They are used in garments like smart shirts, jackets, and gloves that can monitor heart rate, body temperature, or track movement.

- Integrated Sensors: Future garments may include seams that contain embedded sensors, making it possible to monitor health metrics, like blood pressure or physical activity, directly from the garment. These smart seams are poised to change the way we think about clothing, merging fashion with technology.

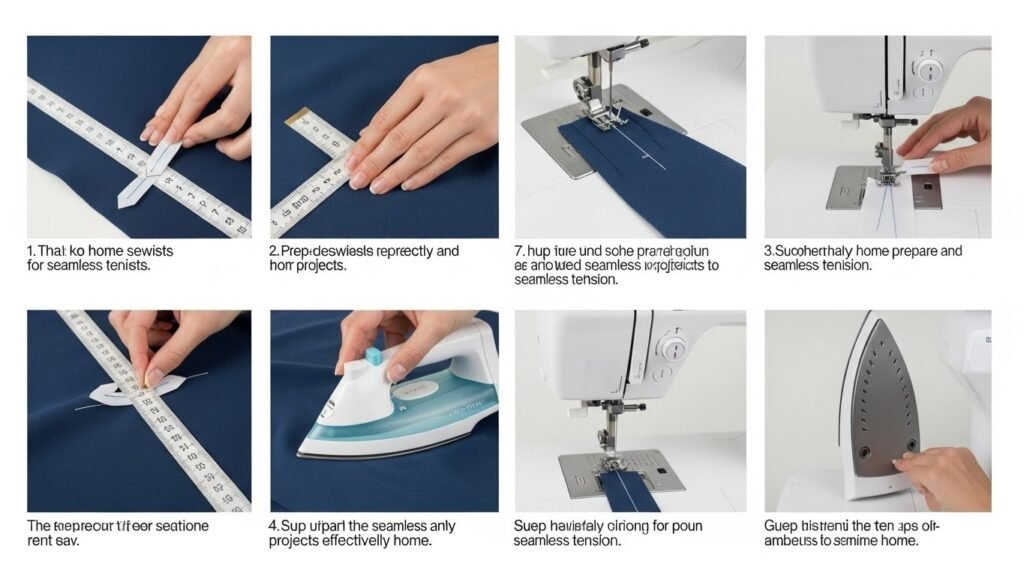

Practical Tips for Sewing Seams at Home

While industrial seam techniques are fascinating, many sewists at home still rely on traditional methods for their projects. Whether you’re a beginner or an experienced sewist, there are practical tips that can help improve your seamwork.

Choosing the Right Sewing Machine for Seams

The sewing machine you use will directly affect the quality of your seams. It’s important to select a machine that suits the type of sewing you plan to do.

- Basic Sewing Machines: For simple sewing tasks, a basic sewing machine with a straight stitch function is sufficient. These machines are great for making plain seams and are easy to operate.

- Advanced Sewing Machines: If you’re working with a variety of fabrics or need more complex seams, an advanced sewing machine with additional stitch options (like zigzag and overlock stitches) is a better choice. These machines are ideal for more intricate projects and allow for more flexibility.

Preparing Fabric for Seam Construction

Properly preparing your fabric before starting to sew is crucial for achieving neat, durable seams.

- Pre-washing Fabric: Always pre-wash your fabric before sewing to prevent shrinkage later. This ensures that the fabric has already undergone any potential shrinking, and the seams will remain intact after the garment is washed.

- Ironing Fabric: Before sewing, iron your fabric to ensure it’s smooth and free of wrinkles. This will help achieve crisp, clean seams and prevent puckering during sewing.

Measuring and Marking for Accurate Seams

Accurate measurements and markings are key to ensuring that your seams are straight and aligned.

- Seam Allowance: Always measure and mark your seam allowances accurately. Most patterns will include a recommended seam allowance, but make sure to measure and mark it before sewing to avoid errors.

- Use of Fabric Marking Tools: Use fabric marking tools, such as chalk or fabric pens, to mark where your seams will go. These markings will guide you as you sew and help ensure your seams are straight and aligned.

Troubleshooting Issues with Seams

Even with careful planning, issues can arise during the sewing process. Understanding how to troubleshoot these common problems can help ensure that your seams come out looking their best.

Dealing with Uneven Stitches

Uneven stitches can make your seams look messy and unprofessional. This is usually caused by improper thread tension or fabric feeding issues.

- Fixing Tension Problems: If your stitches are uneven, first check the tension on your sewing machine. Adjust it according to the fabric you’re using. If you’re working with thicker fabrics, you may need to loosen the tension, while finer fabrics might need tighter tension.

- Ensuring Proper Fabric Feeding: Ensure that the fabric is feeding evenly through the machine. Use your sewing machine’s foot pedal gently to avoid stretching the fabric or causing it to bunch up.

Avoiding Fabric Puckering

Puckering can occur if the seam tension is too tight or if you’re sewing with a fabric that is too delicate.

- Adjusting Tension: If your fabric puckers, loosen the tension on your sewing machine. Additionally, try sewing with a larger needle for delicate fabrics to avoid excessive pressure.

- Using Stabilizers: For lightweight fabrics, using stabilizers or interfacing can help provide extra structure and prevent puckering during sewing.

Fixing Fraying Edges

Fraying is a common problem with certain types of fabric, especially at the edges of seams. It can weaken the seam and cause it to come apart over time.

- Seam Finishing Techniques: To prevent fraying, finish the raw edges of your seams with techniques like overlocking or using pinking shears. These methods will seal the edges and keep your seams intact.

Conclusion

Seam types are essential elements of garment construction, affecting everything from durability and strength to the fit and appearance of the final product. Understanding the various seam types, their specific uses, and the techniques involved can significantly improve the quality of your sewing projects. Whether you are a beginner or an experienced sewist, choosing the right seam is crucial to achieving both functionality and aesthetic appeal in your garments.

By mastering seam finishing techniques and learning to choose the right seams for the fabric type and garment function, you can ensure that your creations are both durable and comfortable. Additionally, with the rise of advanced seam technologies such as laser seaming and conductive seams, the future of garment construction looks promising, offering even more possibilities for innovation and sustainability in fashion.

As you continue to experiment and hone your sewing skills, remember that the choice of seam is just as important as the fabric and design itself. Take the time to explore different seam types, try new techniques, and test your seams for strength and durability. The result will be garments that not only look great but also stand the test of time.

FAQs

What is the difference between a plain seam and a French seam?

A plain seam is a basic seam where two fabric pieces are stitched together with the edges left raw. It is most commonly used for woven fabrics. On the other hand, a French seam encloses the raw edges within the seam itself, making it a cleaner and more durable option. French seams are ideal for lightweight fabrics like silk and chiffon.

Can I use an overlock seam for all fabric types?

Overlock seams are versatile and can be used for many fabric types, particularly knits and stretchy fabrics. However, for heavier fabrics like denim or canvas, stronger seams like flat-felled seams are more suitable, as they provide better durability.

How do I prevent seams from fraying?

To prevent seams from fraying, you can use seam finishing techniques like overlocking, pinking shears, or binding. These methods help seal raw edges and prevent fabric from unraveling over time.

What seam type is best for denim?

For denim, flat-felled seams are ideal. These seams are strong and durable, which is essential for denim’s heavy weight. They also offer a neat and professional finish, making them a popular choice for jeans and workwear.

What are some common mistakes when sewing seams?

Some common mistakes include using the wrong needle type for the fabric, incorrect tension settings, and failing to finish seam edges properly. These issues can lead to weak or uneven seams. Always test your settings and techniques before sewing the final garment.

How can I achieve a professional finish with seams?

Achieving a professional finish requires using the appropriate seam for your fabric, ensuring the correct thread tension, and properly finishing raw edges to prevent fraying. Additionally, techniques like topstitching and blind hems can help add a polished, professional look to your garment.

What is the best seam for activewear?

For activewear, seams that allow for flexibility and stretch are essential. Zigzag seams and overlock seams are excellent choices because they maintain the garment’s elasticity while providing durability. These seams help ensure comfort and movement during physical activities.

Can I use laser seaming for home sewing projects?

Laser seaming is a highly advanced technique typically used in industrial garment production. It’s not typically available for home sewers, as it requires specialized equipment. However, you can achieve similar results by using overlocking or serging to finish seams neatly and securely at home.

What is the best seam for formal wear?

For formal wear, French seams and blind hem seams are the best choices. French seams offer a clean, polished interior by enclosing raw edges, while blind hems provide an invisible finish for hems and cuffs, perfect for formal pants, skirts, and dresses.

How do I choose the right seam for my project?

When choosing a seam, consider the fabric type, the garment’s intended use, and the durability required. For lightweight fabrics, delicate seams like French seams work best, while heavy fabrics like denim require stronger seams like flat-felled. Always test your seam choices on scrap fabric before starting your main project.